Product Testing Equipment

By possessing Alpha Cabin/Apamat, we can secure own testing capabilities and competence to collaborate with public certification testing agencies.-

Alpha Cabin

Sound absorption and noise reduction measurement -

Apamat

Sound absorption and noise reduction measurement -

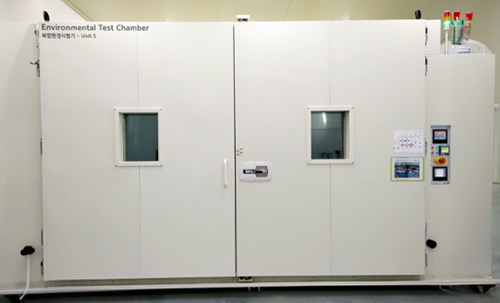

Temperature and Humidity Chamber

Heat resistance testing for products and fabrics Testing range (-50 to 150°C) -

Hot & Cold Press Tester

Sample preparation, sample condition realization / property testing -

Constant Temperature and Humidity Device

Specimen production, implementation of specimen conditions / physical property testing -

Universal Material Tester

Specimen production, implementation of specimen conditions / physical property testing -

Combustibility Tester

Flammability testing -

Oil Resistance Tester

Oil resistance and oil penetration testing -

Water Resistance Tester

Water resistance and penetration testing -

Specimen Punching Machine

for producing specimens for material testing -

Falling Ball Impact Tester

-

Pure Manufacturing Device

-

Infrared Composite Chamber

Infrared composite tester for cold resistance, heat resistance, humidity resistance, and thermal cycling -

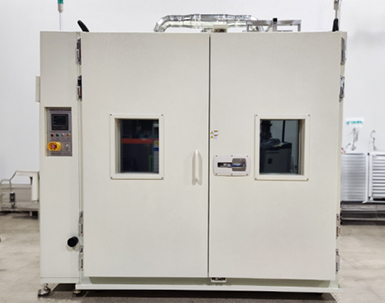

Constant Temperature and Humidity Chamber

Cold resistance, heat resistance, humidity resistance, thermal cycling

-

Karcher

high-pressure car wash test -

Odorless room within the corporate-affiliated research institute

Sound absorption and sound insulation measurement tests for fabrics and products

※ Also equipped with various environmental testers such as combustibility testers, water/oil resistance testers, specimen punching machines, digital scales, and steel ball drop tester

Material Testing/Inspection Equipment

Have yarn quality management and test analysis system, and developed color fiberQuality control for raw materials and yarn marketability

-

Incoming raw material inspection

Moisture content testing, viscosity measurement, appearance inspection -

Manufacturing process control

Fiber fineness, fiber length, strength, elongation, number of turns, shrinkage rate, oil content, etc. -

Finished products

Shipping inspection -

Quality maintenance management

- Product-specific management standards

- Operating condition check by process

- Physical property analysis and appearance inspection of finished products

Physical property verification of the yarn

-

Agitator for dispersion verification

-

Bulkiness

(specific volume) meter -

Inspection dryer

-

Fiber fineness/denier meter

-

Viscometer

-

Moisture content meter

(raw materials)